阅读量:0

STM32F103ZET6+TMC2209控制步进电机正反转

1. 步进电机介绍

- 本实验采用2项步进电机,电机只有2项,A+\A-\B+\B-。

- 电机步距角1.8°

2 驱动器TMC2209介绍

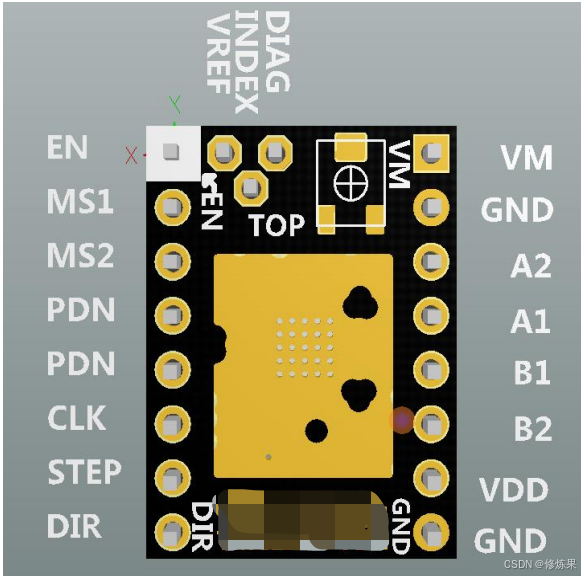

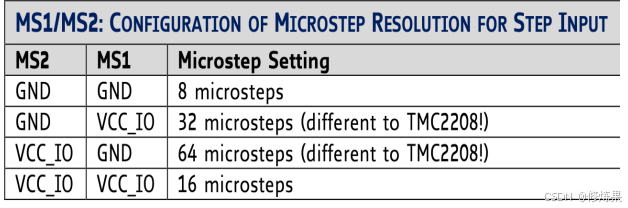

2.1 引脚图及其功能

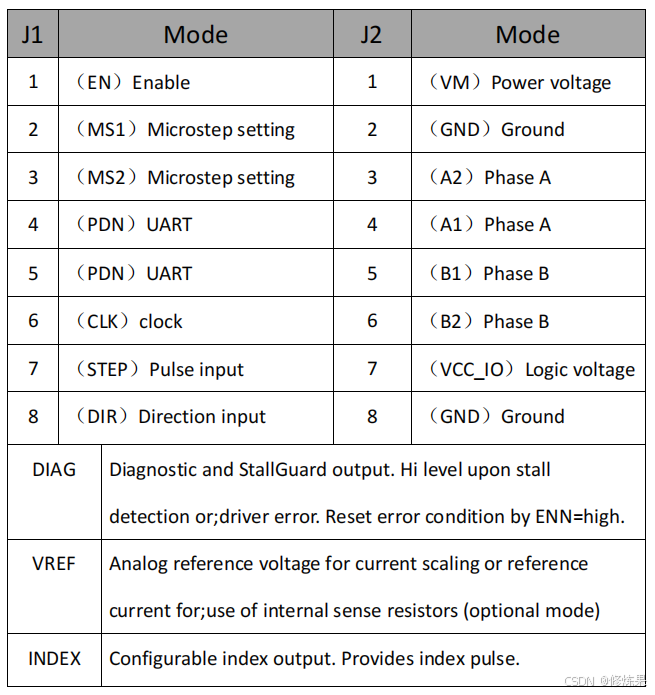

2.2 细分介绍

- 8细分控制精度=1.8°/8=0.225°,电机转一周需要1600个脉冲。

- 16细分控制精度=1.8°/16=0.1125°,电机转一周需要3200个脉冲。

- 32细分控制精度=1.8°/32=0.05625°,电机转一周需要6400个脉冲。

- 64细分控制精度=1.8°/64=0.0140625°,电机转一周需要12800个脉冲。

满足绝大多数精度场景,如低精度机床、家电、3D打印等。

2.3 TMC控制驱动器接法

这里只需要使用13个引脚

EN:控制器使能引脚,接GND, 电机才能工作。

DIR:控制方向,这个引脚的高\低电平分别控制正\反转

VM:给电机的电压(4.75—>28VDC),可以选择24V电源供电,没24V直流电源可以在网上买一个。电机电压5V可能导致电机丢步,尽量选择24V的直流电源。

GND:VM的GND

STEP: 控制脉冲,一个占空比为50%高电平、一个占空比50%的低电平为一个脉冲。

MS1\MS2: 控制细分,参考2.2节

VDD: 给TMC2209供电,供+5V供电。

GND: VDD的GND

A1\A2\B1\B2: 参考第1节的电机。

3 控制器介绍

- STM32F103ZET6(正点原子V3)

3.1 确定控制引脚

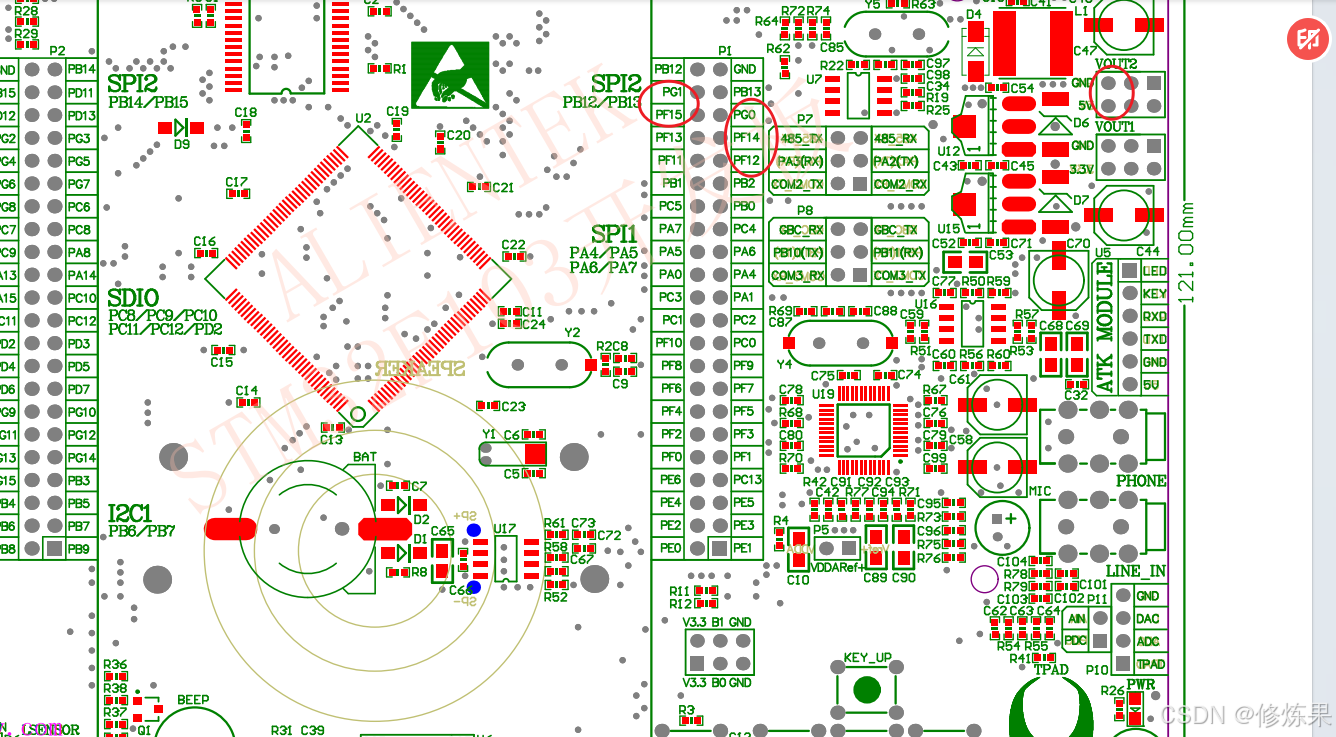

- 将下面的引脚与2.3的引脚连接,具体位置如下图红圈位置。

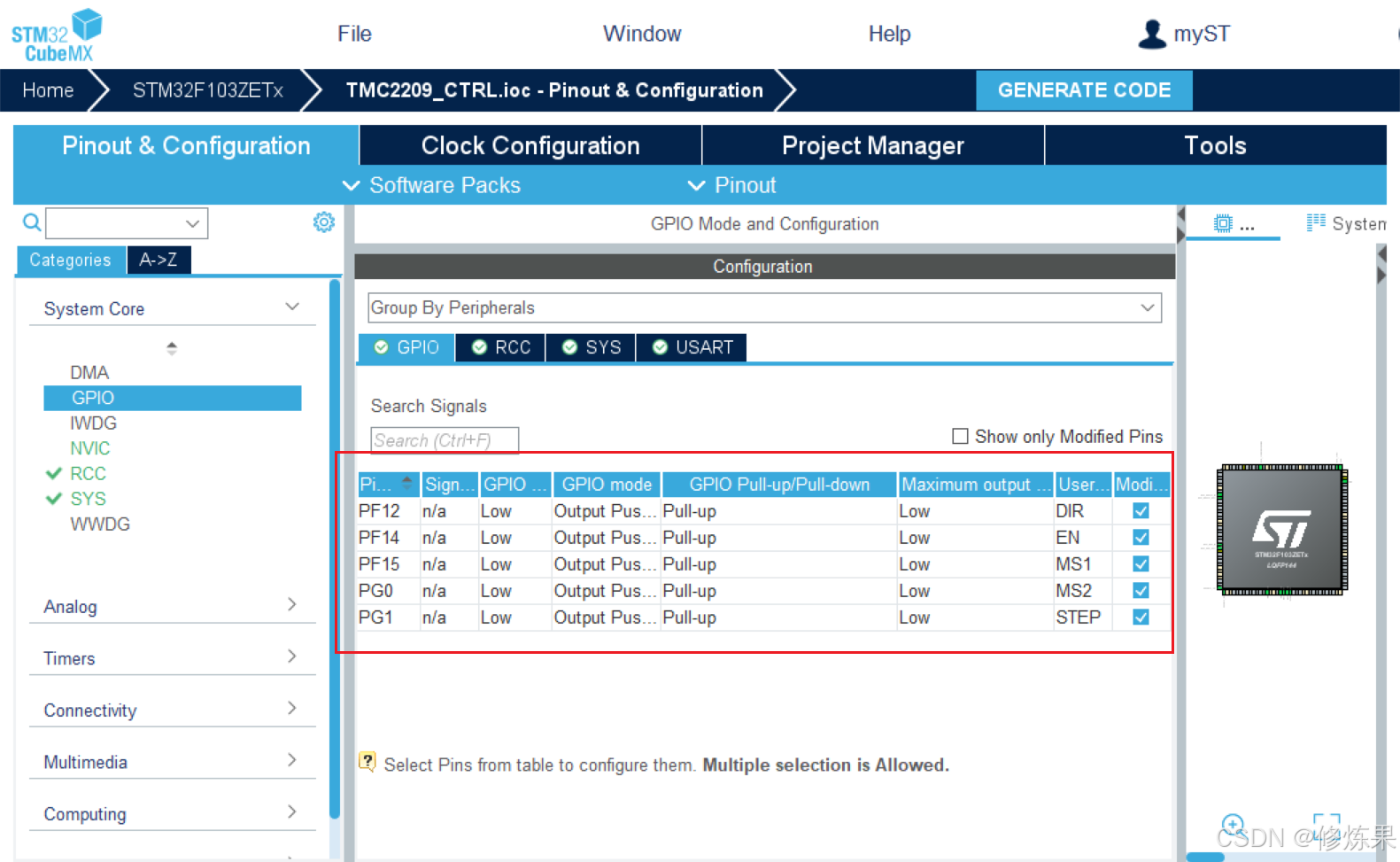

DIR: PF12/FSMC_A6

STEP: PG1/FSMC_A11

EN: PF14/FSMC_A8

MS1: PF15/FSMC_A9

MS2: PG0/FSMC_VA10

VDD: 见下图红圈位置

GND: 见下图红圈位置

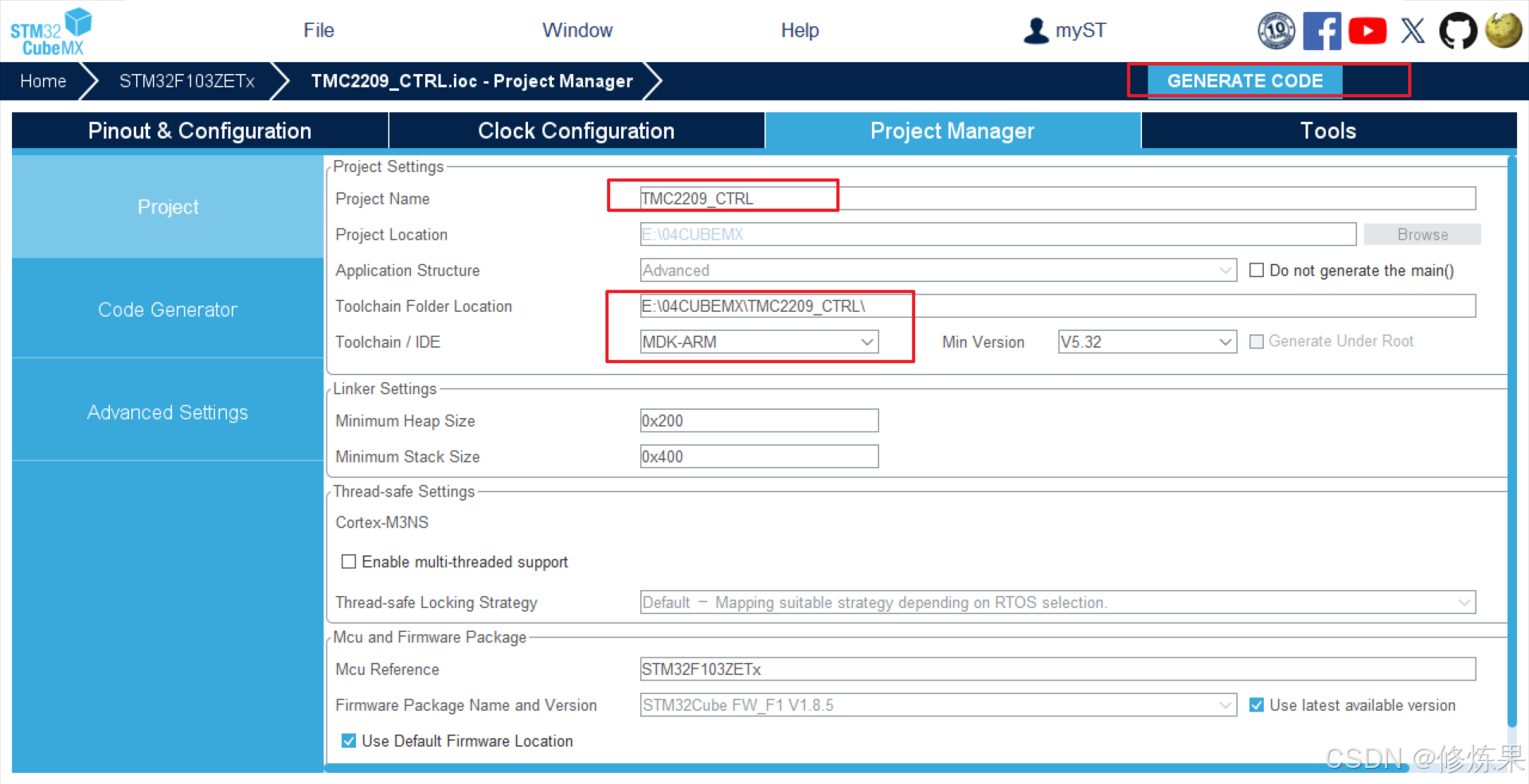

3.2 UBEMX配置

3.2.1 GPIO配置

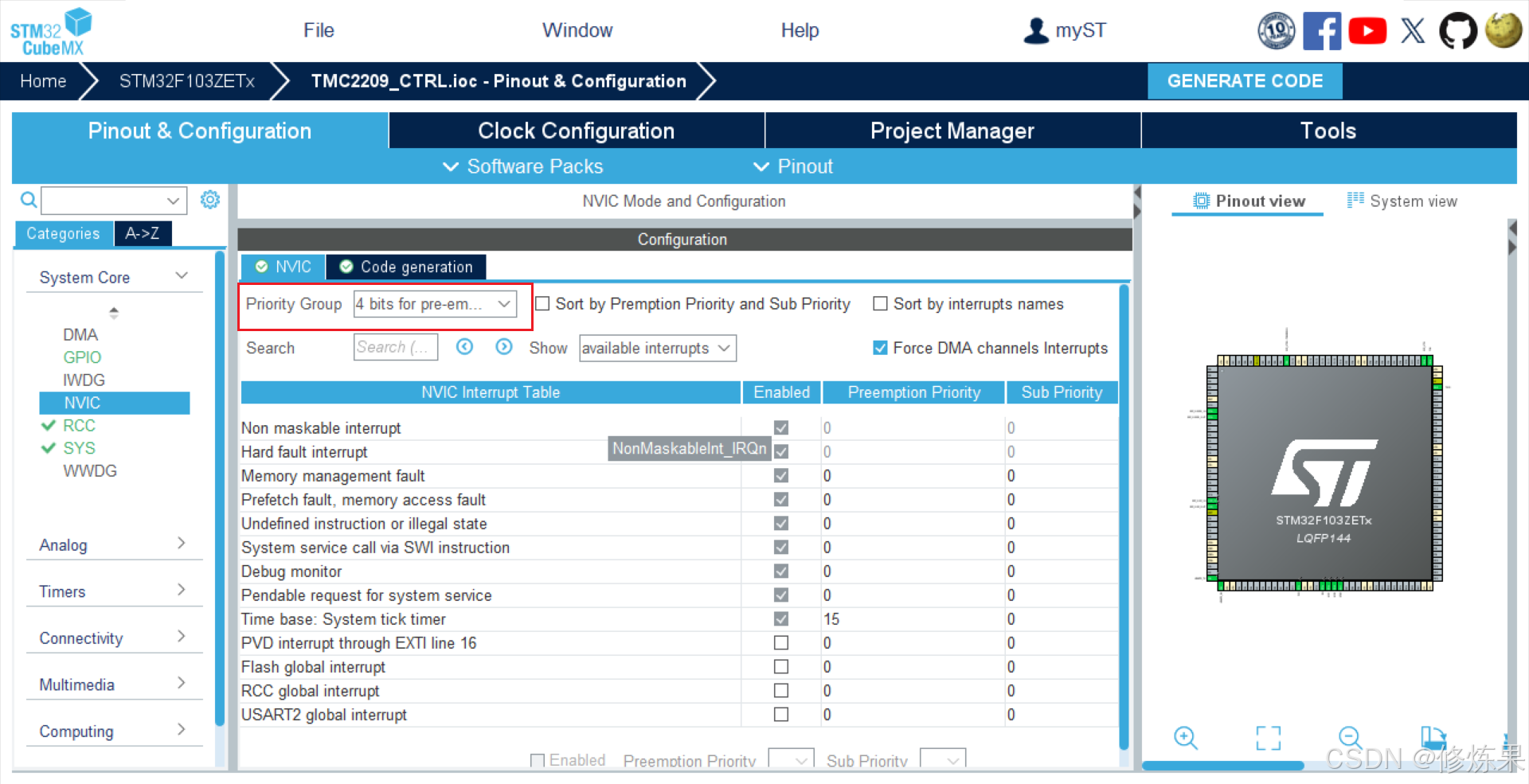

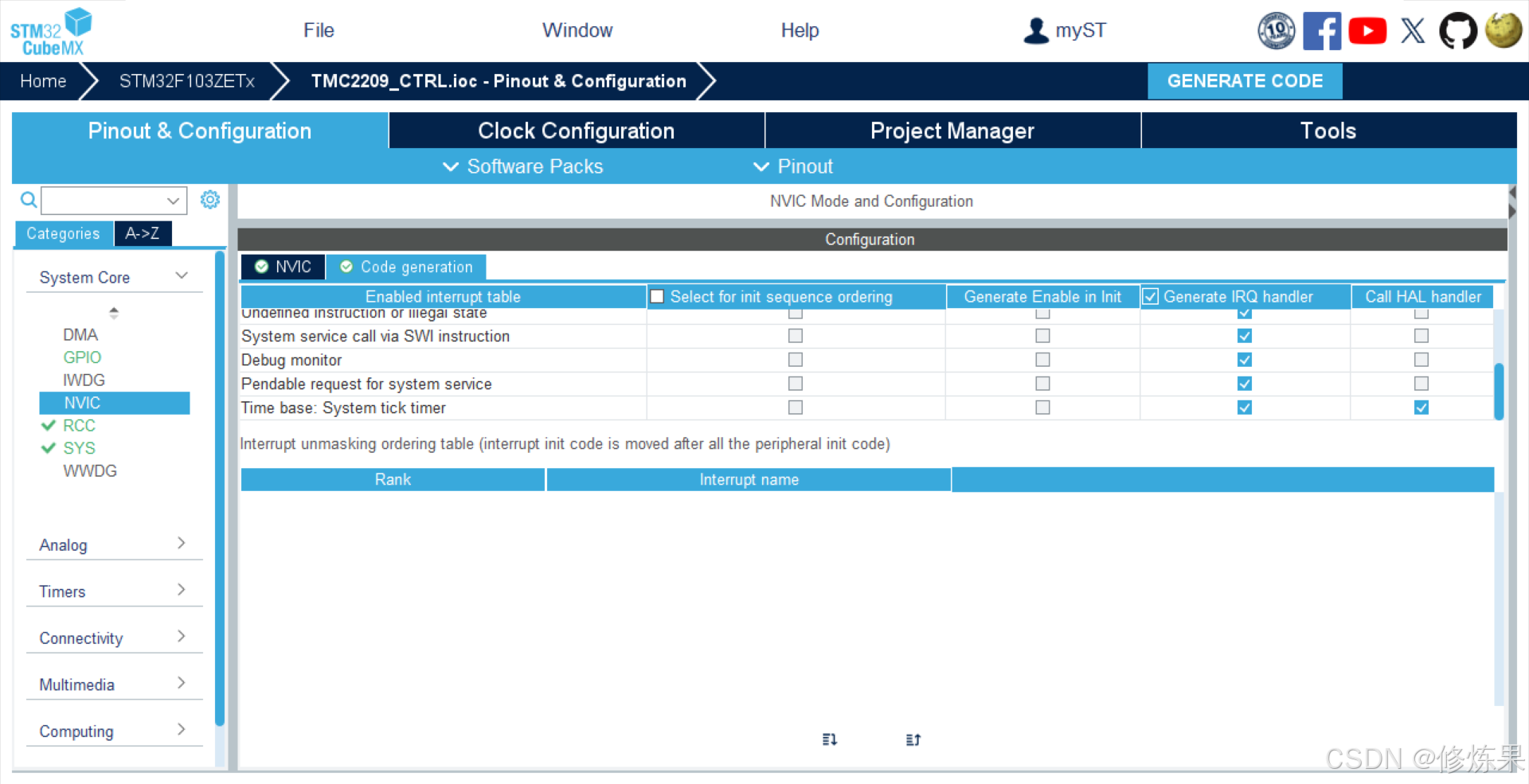

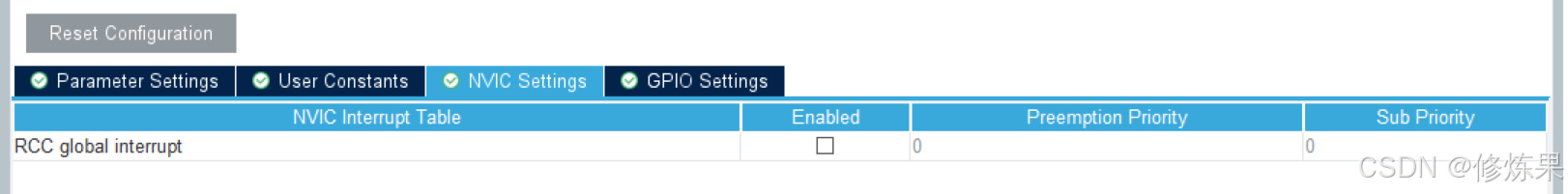

3.2.2 NVIC配置

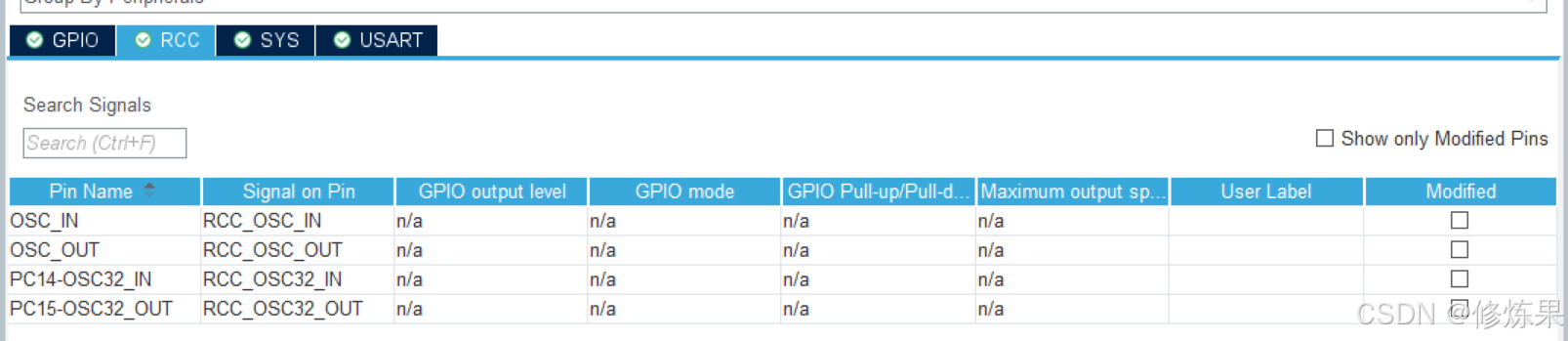

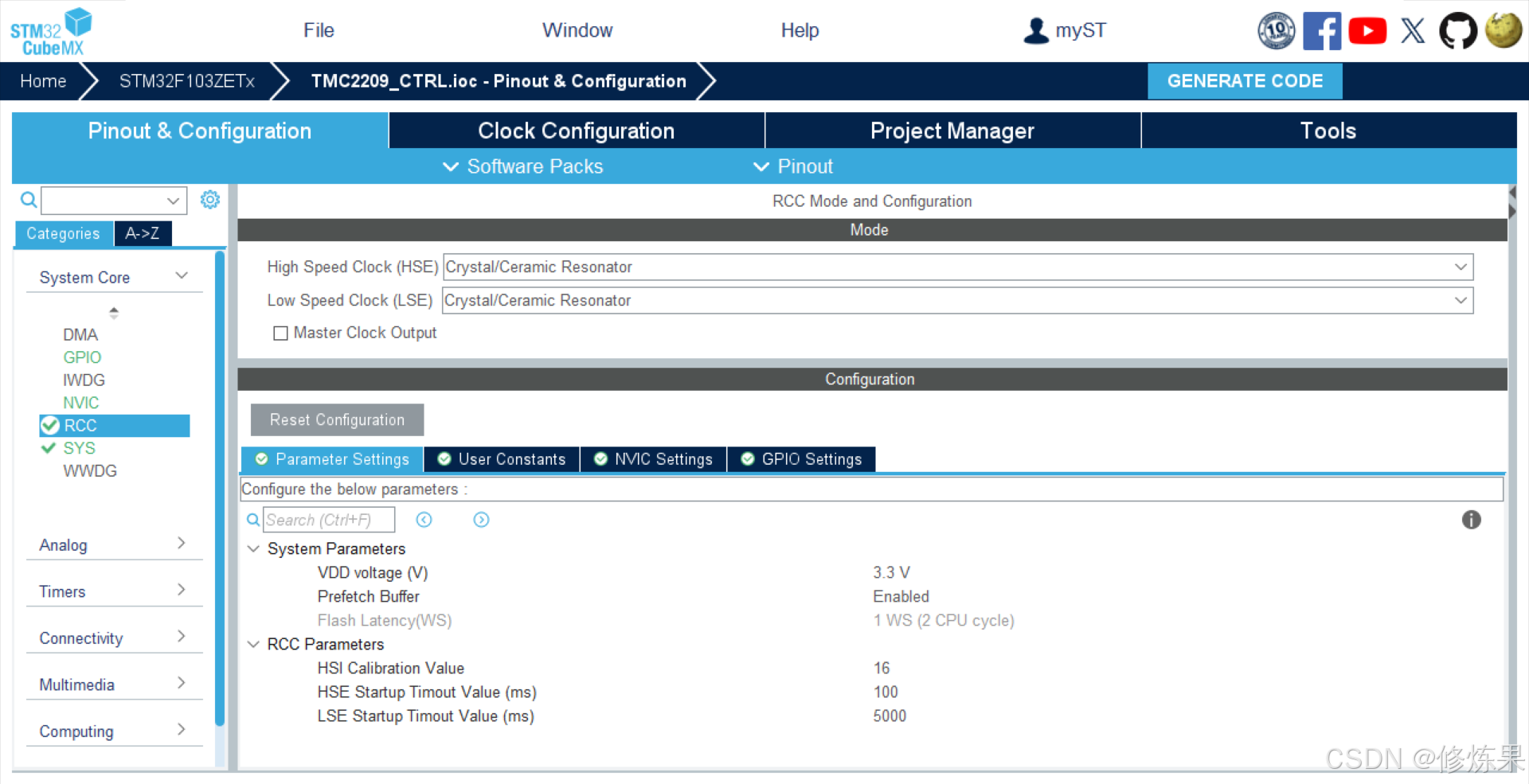

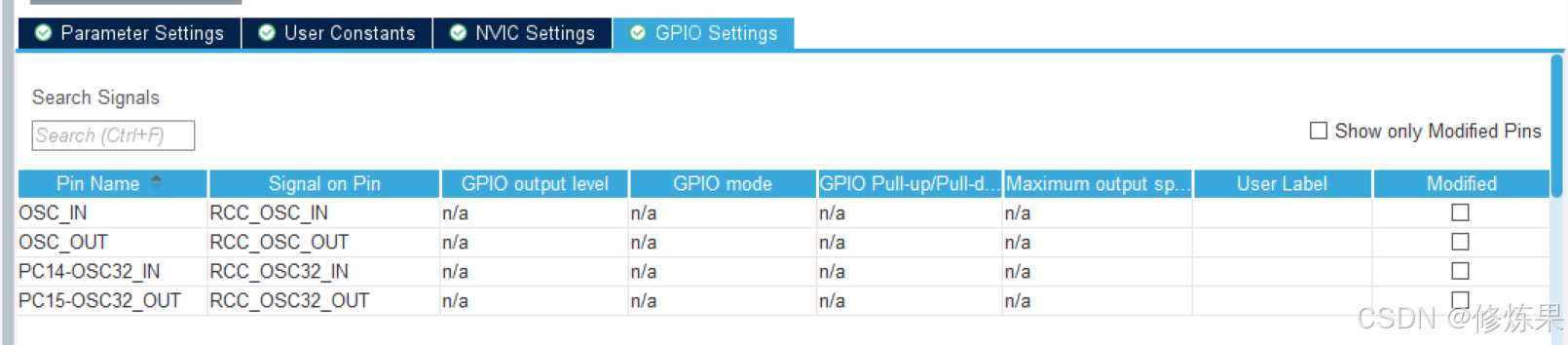

3.2.3 RCC配置

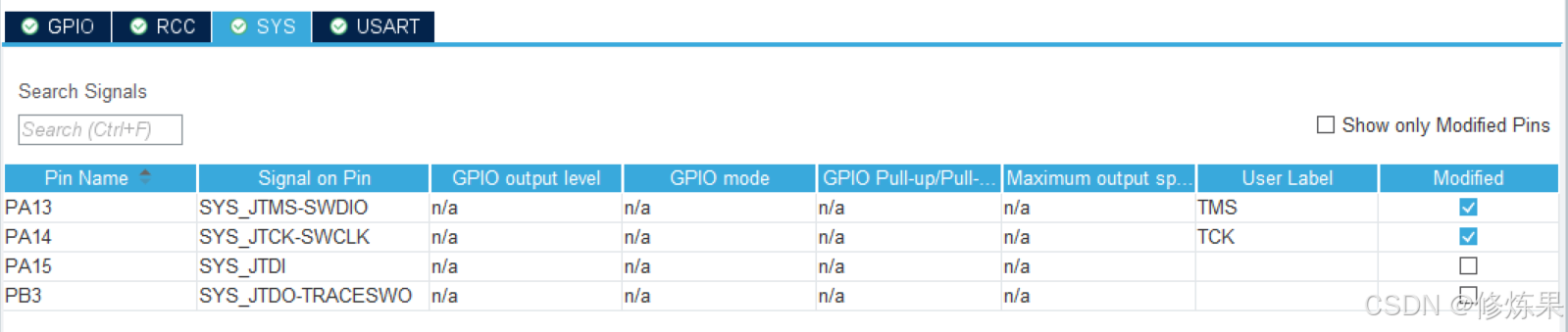

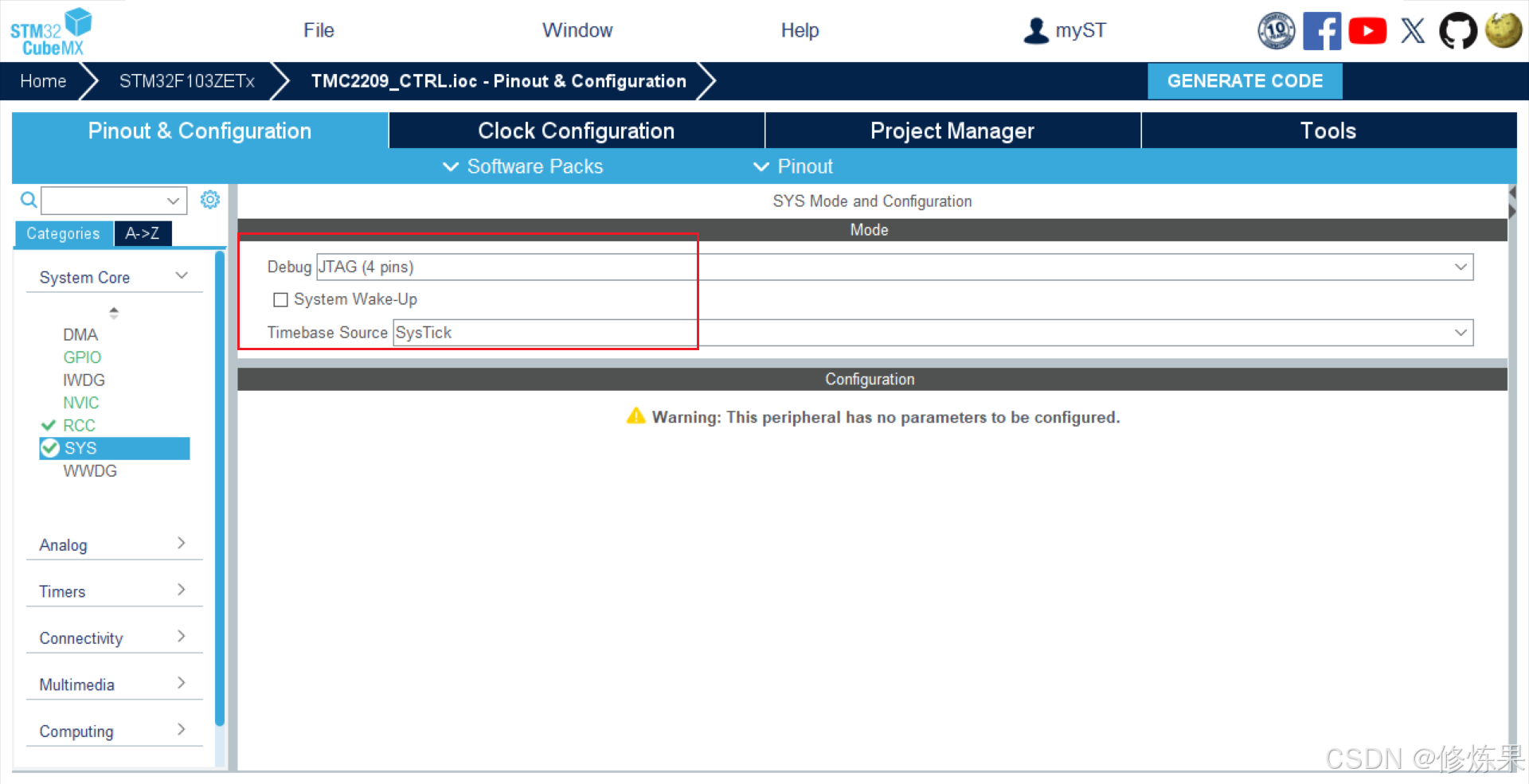

3.2.4 SYS配置

- 用的ST-link V2的仿真器,选择下面这个:

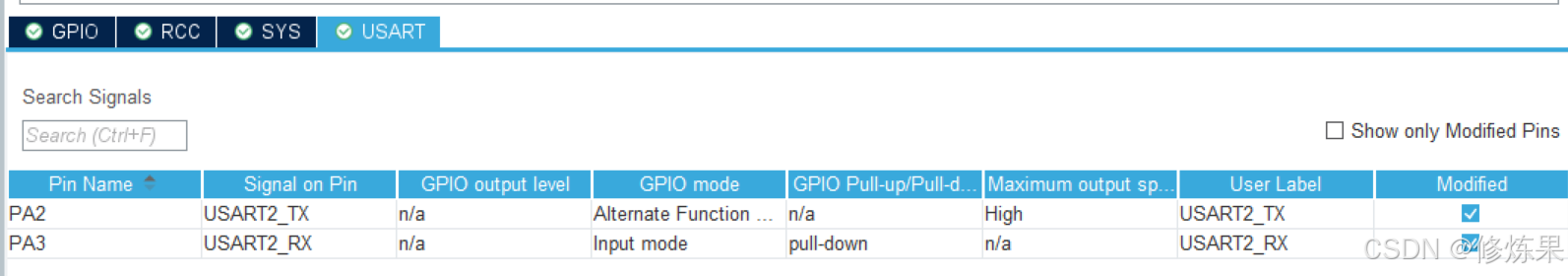

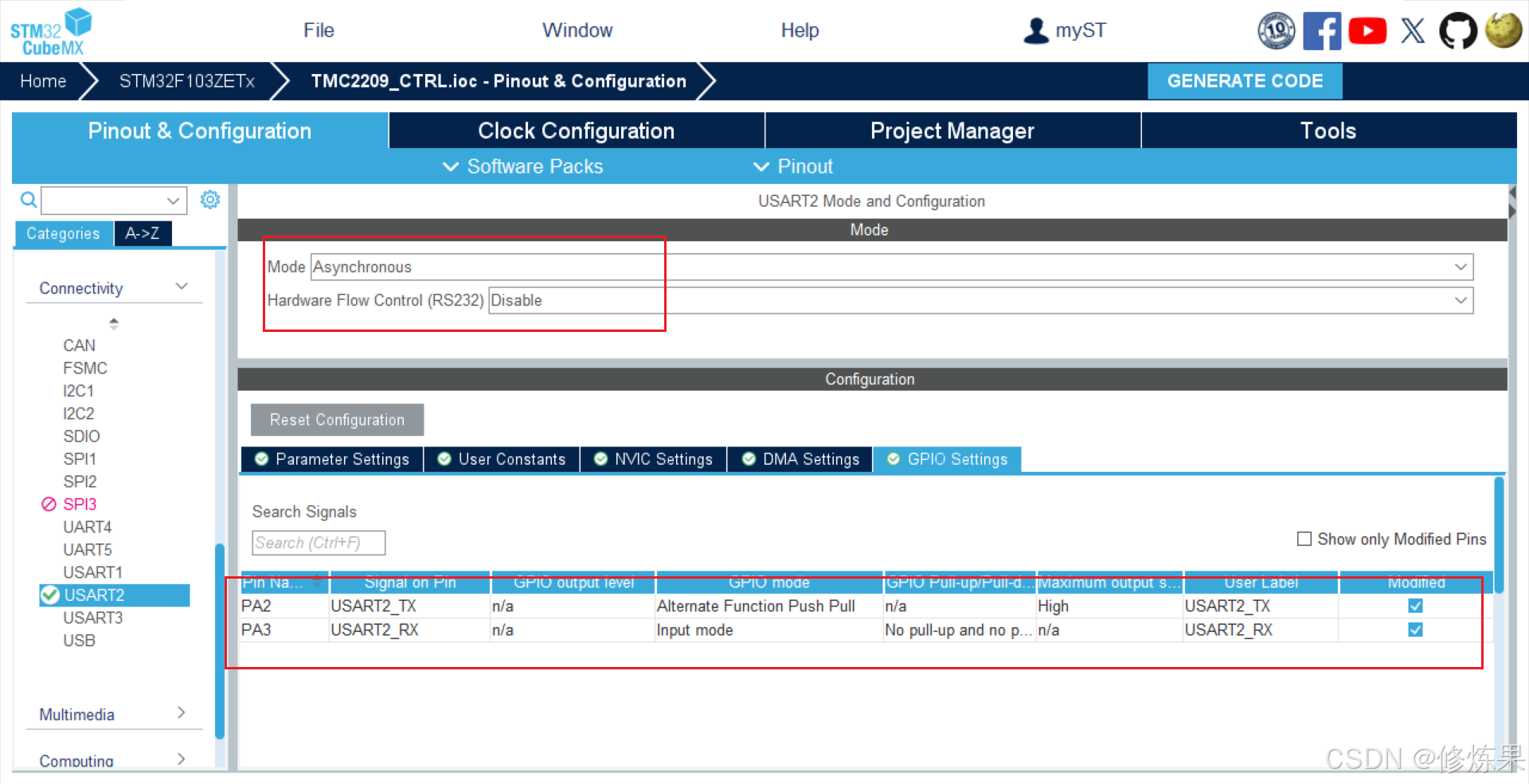

3.2.5 USRAT2配置(PS:没用上可以跳过)

3.2.6 保存并生成工程

4 代码部分

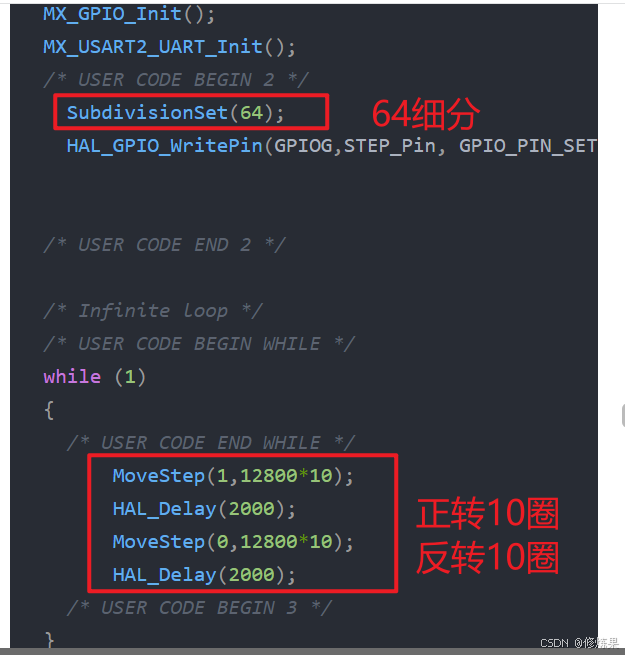

主要修改main.c,其他的不用管。

/* USER CODE BEGIN Header */ /** ****************************************************************************** * @file : main.c * @brief : Main program body ****************************************************************************** * @attention * * Copyright (c) 2024 STMicroelectronics. * All rights reserved. * * This software is licensed under terms that can be found in the LICENSE file * in the root directory of this software component. * If no LICENSE file comes with this software, it is provided AS-IS. * ****************************************************************************** */ /* USER CODE END Header */ /* Includes ------------------------------------------------------------------*/ #include "main.h" #include "usart.h" #include "gpio.h" /* Private includes ----------------------------------------------------------*/ /* USER CODE BEGIN Includes */ /* USER CODE END Includes */ /* Private typedef -----------------------------------------------------------*/ /* USER CODE BEGIN PTD */ /* USER CODE END PTD */ /* Private define ------------------------------------------------------------*/ /* USER CODE BEGIN PD */ /* USER CODE END PD */ /* Private macro -------------------------------------------------------------*/ /* USER CODE BEGIN PM */ /* USER CODE END PM */ /* Private variables ---------------------------------------------------------*/ // UART_HandleTypeDef huart2a; /* USER CODE BEGIN PV */ /* USER CODE END PV */ /* Private function prototypes -----------------------------------------------*/ // static void MX_GPIO_Init(void); // static void MX_USART2_UART_Init(void); void SystemClock_Config(void); /* USER CODE BEGIN PFP */ /* USER CODE END PFP */ /* Private user code ---------------------------------------------------------*/ /* USER CODE BEGIN 0 */ void SubdivisionSet(uint8_t i); //细分设置 void MoveStep(uint8_t DIR_Flag,uint32_t Step); //电机移动多少步 /* USER CODE END 0 */ /** * @brief The application entry point. * @retval int */ int main(void) { /* USER CODE BEGIN 1 */ /* USER CODE END 1 */ /* MCU Configuration--------------------------------------------------------*/ /* Reset of all peripherals, Initializes the Flash interface and the Systick. */ HAL_Init(); /* USER CODE BEGIN Init */ /* USER CODE END Init */ /* Configure the system clock */ SystemClock_Config(); /* USER CODE BEGIN SysInit */ /* USER CODE END SysInit */ /* Initialize all configured peripherals */ MX_GPIO_Init(); MX_USART2_UART_Init(); /* USER CODE BEGIN 2 */ SubdivisionSet(64); //细分设置为64 HAL_GPIO_WritePin(GPIOG,STEP_Pin, GPIO_PIN_SET); //STEP设置为高 /* USER CODE END 2 */ /* Infinite loop */ /* USER CODE BEGIN WHILE */ while (1) { /* USER CODE END WHILE */ MoveStep(1,12800*10); //正转一圈 HAL_Delay(2000); //延时2S MoveStep(0,12800*10); //反转一圈 HAL_Delay(2000); //延时2S /* USER CODE BEGIN 3 */ } /* USER CODE END 3 */ } /** * @brief SubdivisionSet * 细分设置 * @retval None */ void SubdivisionSet(uint8_t i) { if(i==8) { HAL_GPIO_WritePin(GPIOG,MS2_Pin, GPIO_PIN_RESET); HAL_GPIO_WritePin(GPIOF,MS1_Pin, GPIO_PIN_RESET); } else if(i==32) { HAL_GPIO_WritePin(GPIOG,MS2_Pin, GPIO_PIN_RESET); HAL_GPIO_WritePin(GPIOF,MS1_Pin, GPIO_PIN_SET); } else if(i==64) { HAL_GPIO_WritePin(GPIOG,MS2_Pin, GPIO_PIN_SET); HAL_GPIO_WritePin(GPIOF,MS1_Pin, GPIO_PIN_RESET); } else { HAL_GPIO_WritePin(GPIOG,MS2_Pin, GPIO_PIN_SET); HAL_GPIO_WritePin(GPIOF,MS1_Pin, GPIO_PIN_SET); } } /** * @brief DelayNop * 延时 * @retval None */ void DelayNop(uint8_t i) { uint32_t j; do { for(j=0;j<100;j++){;} }while(i--); } /** * @brief MoveStep * 电机移动多少步 * @retval None */ void MoveStep(uint8_t DIR_Flag,uint32_t Step) { //uint8_t j=200; uint32_t j=1; uint32_t i; //电机使能 HAL_GPIO_WritePin(GPIOF,EN_Pin, GPIO_PIN_RESET); if(DIR_Flag) { //正转 HAL_GPIO_WritePin(GPIOF,DIR_Pin, GPIO_PIN_SET); } else { //反转 HAL_GPIO_WritePin(GPIOF,DIR_Pin, GPIO_PIN_RESET); } for(i=0;i<Step;i++) { //发送脉冲 HAL_GPIO_WritePin(GPIOG,STEP_Pin, GPIO_PIN_RESET); //if(j>1) j--; //else; DelayNop(j); HAL_GPIO_WritePin(GPIOG,STEP_Pin, GPIO_PIN_SET); DelayNop(j); } HAL_Delay(10); //电机非使能 HAL_GPIO_WritePin(GPIOF,EN_Pin, GPIO_PIN_SET); } /** * @brief System Clock Configuration * @retval None */ void SystemClock_Config(void) { RCC_OscInitTypeDef RCC_OscInitStruct = {0}; RCC_ClkInitTypeDef RCC_ClkInitStruct = {0}; /** Initializes the RCC Oscillators according to the specified parameters * in the RCC_OscInitTypeDef structure. */ RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI; RCC_OscInitStruct.HSIState = RCC_HSI_ON; RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT; RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON; RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSI_DIV2; RCC_OscInitStruct.PLL.PLLMUL = RCC_PLL_MUL9; if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK) { Error_Handler(); } /** Initializes the CPU, AHB and APB buses clocks */ RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK |RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2; RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK; RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1; RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV2; RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV1; if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_1) != HAL_OK) { Error_Handler(); } } /* USER CODE BEGIN 4 */ /** * @brief USART2 Initialization Function * @param None * @retval None */ //void MX_USART2_UART_Init(void) //{ // /* USER CODE BEGIN USART2_Init 0 */ // /* USER CODE END USART2_Init 0 */ // /* USER CODE BEGIN USART2_Init 1 */ // /* USER CODE END USART2_Init 1 */ // huart2a.Instance = USART2; // huart2a.Init.BaudRate = 115200; // huart2a.Init.WordLength = UART_WORDLENGTH_8B; // huart2a.Init.StopBits = UART_STOPBITS_1; // huart2a.Init.Parity = UART_PARITY_NONE; // huart2a.Init.Mode = UART_MODE_TX_RX; // huart2a.Init.HwFlowCtl = UART_HWCONTROL_NONE; // huart2a.Init.OverSampling = UART_OVERSAMPLING_16; // if (HAL_UART_Init(&huart2a) != HAL_OK) // { // Error_Handler(); // } /* USER CODE BEGIN USART2_Init 2 */ /* USER CODE END USART2_Init 2 */ //} /** * @brief This function is executed in case of error occurrence. * @retval None */ void Error_Handler(void) { /* USER CODE BEGIN Error_Handler_Debug */ /* User can add his own implementation to report the HAL error return state */ __disable_irq(); while (1) { } /* USER CODE END Error_Handler_Debug */ } #ifdef USE_FULL_ASSERT /** * @brief Reports the name of the source file and the source line number * where the assert_param error has occurred. * @param file: pointer to the source file name * @param line: assert_param error line source number * @retval None */ void assert_failed(uint8_t *file, uint32_t line) { /* USER CODE BEGIN 6 */ /* User can add his own implementation to report the file name and line number, ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */ /* USER CODE END 6 */ } #endif /* USE_FULL_ASSERT */ - 这边的代码是选择64细分,正转10圈-等待2S-反转10圈-等待2S。

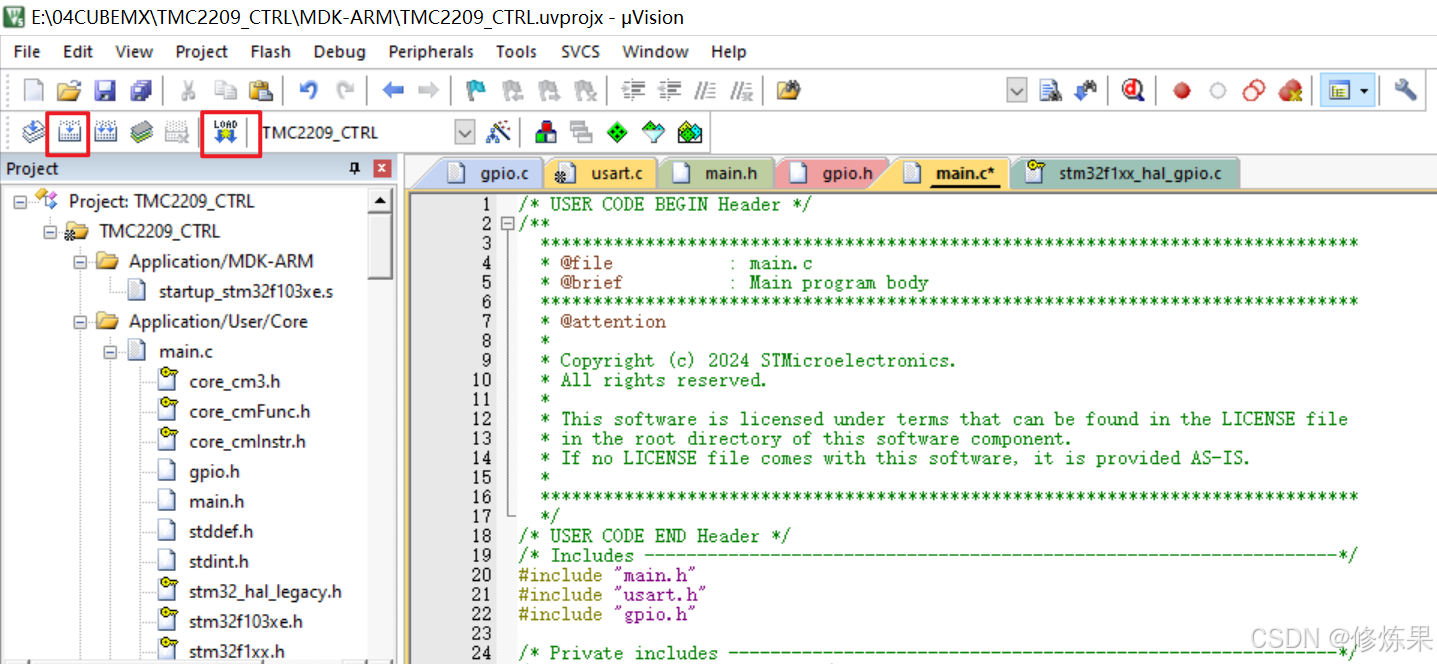

- 编译代码烧录到单板

仿真器配置参考link中13节。

- 这样,就可以控制电机正反转啦。

ps: 正点原子STM32战舰版V3的板子每次烧录需要摁红色reset按钮,烧录才能生效。